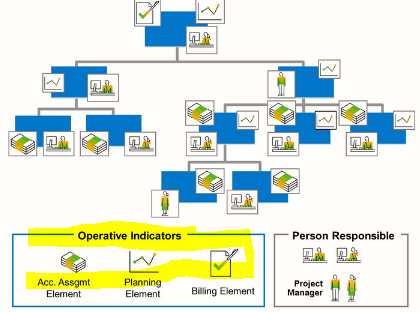

Use and Purpose of Operative Indicators in WBS elements

When a customer Requests for ATO or ETO process where we create a Project with Integration between SD and PS ( project systems)

As a First step we create a Project in CJ20N and under the Project we will Create Multiple WBS elements which has to be set for Operative Indicators

This article deals with Operative Indicators in WBS elements.

WE Use Operative Indicators to define characteristics of WBS and to specify which tasks WBS can perform during Execution

In General, we have three Operative Indicators such as

1. Planning Indicator

2. Account Assignment Indicator

3. Billing Indicator

Planning Element:WBS Elements will be set for planning Element,if we we want a plan cost to be enabled

For Example, While Creating a Project- Manufacturing an Equipment. We will Create different WBS elements for each Level such as Design, Procurement of components, Production, Assembly and Installation. During Each state some cost is incurred and we plan in advance based on the Activities

This level of Planning the Cost will be only enabled and updated at WBS elements where it is Flagged as Planning Element.

Account Assignment Element:

WBS element will be flagged for Account Assignment element if any Actual Cost is posted

For Example, While Creating a Project- Manufacturing an Equipment. We will Create different WBS elements for each Level such as Design, Procurement of components, Production, Assembly and Installation. In each level of WBS elements while Confirming WBS element we will incur the cost and that Cost is called Actual Cost.

When Posting Actual , WBS should be flagged as Account Assignment element else Actual cost will not be allowed

Billing Element:

WBS element will be flagged for Billing Element if Revenu is Planned and Posted.

For example, When we are created a Customer Project , we obviously expect some Revenue either directly or with Milestones, in such cases we flag WBS as Billing element which ensures Posting of Revenue

This post is very simple to read and appreciate without leaving any details out. Great work ! cloud call center software

ReplyDeleteAbove post are good and easy to read!

ReplyDeletesap brim implementation solutions