This Article focuses on Requirement Type and how it is determined in Sales Order. Also the strategy of Requirement and its Usage

Definition of Requirements Type:

Requirement Type Identifies different Requirements like Sales Order, Delivery Requirements, individual Customer Requirements, Make To Order or Assembly to Order. Requirements Type uses Planning strategy which has specific strategy for specific Process

Requirements Type along with Requirements Class plays a Significant role in determining relevant Functions like,

Costing,

Settlement,

Result analysis,

Accounting Indicators,

Special Stock Indicators,

Valuation settings

Determining the Requirements Type:

To determine Requirements Type at Sales Order, a sequence of Strategies are defined in Standard

Let us check these Strategies

1. At First, system will check the MATERIAL MASTER--> MRP 3 View-->Strategy Group

Checks in OPPS for Assignment of Strategy group to Requirements Type

2. If the Strategy Group field is empty, as Second Strategy system will look for MRP Group field in MRP 1 View

system check OPPU for MRP Group and Plant Combination for identifying Strategy Group and again OPPS for Requirement Type determination

3. If No MRP type is filled , as Third Strategy, system will check MATERIAL TYPE and matchs the definition of MATERIAL TYPE with MATERIAL GROUP to find Requirements Type

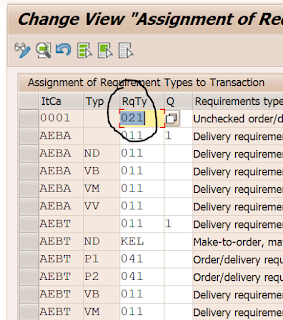

4. If the above also Not matches, then system will look for ITEM CATEGORY + MRP types in the Configuration OVZI

5. If there is no Requirement type for ITEM CATEGORY+ MRP, then system will only look for ITEM CATEGORY alone to determine Requirement Type

If there is no requireement type is maintain for ITEM CATEGORY as well, then system Considers that the transaction is not relevant for Requirement Type

We will see how this will work in an Practical session in Next blog

Thank you

Hi Santosh sir,

ReplyDeleteVery powerful documents you are sharing..keep it up.

Nice information about the requirement type and it's role.

ReplyDeleteThajks,

Amol Datir