Today , we discuss on how an Output type is determined in the sales Order Header

We all know, Output is determined based on the CONDITION TECHNIQUE for Item level

Condition Technique follow

1. Creation of Condition Tables

2. Creation of Access Sequence

3. Creation of Condition types

4. Assigning Condition Tables to Access Sequence

5. Assigning Access sequence to Condition Type

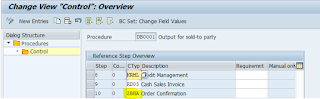

6. Assigning Condition types to Output Procedure

and Finally

7. Condition Records

As we need an Output to be determined at the Header level of sales Order, we dont need to follow CONDITION TECHNIQUE, then how an Output is determined ??

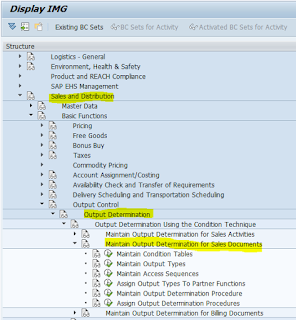

Let us see the Configuration of Output type in SPRO

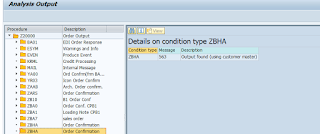

1. Define Output type ZBHA - ( Copy of BA00 Order confirmation)

in output type Properties, don't assign any Access sequence and uncheck field ACCESS TO CONDITION

If access to conditions Is Unchecked, then system will try to fetch the Header condition from the customer master

3. in Transaction code V/46, assign output to DB ( which is customer Application)

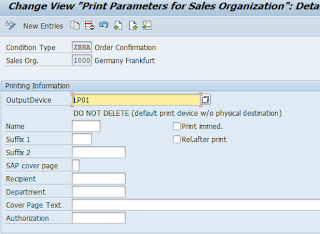

4. Now Maintain Print Parameters for this Output type in Configuration

Remember this step is necessary as we don't have access sequence and Condition records to this header Condition

5. Create a sales Order and check the Output

please test yourselves and let me know if any issues?

Nice content a d good presentatiin

ReplyDeleteThanks for this document

ReplyDeletevery well drafted

ReplyDelete