In the Configuration of REASON FOR REJECTION, we have three indicators .

They are

NRP : Not relevant for Print

OLI : Resource Item Open

BIC : Not relevant for Billing.

We will focus in this article on OLI indicator.

Screenshot:

Business Requirement:

We mainly use OLI indicator in Service Items which are more used either in SAP Customer Service Or Project Systems. Normally when we set Reason for Rejection for a item at the Sales document , the item is considered as Closed and it will not be processed in the subsequent document

But when we set OLI indicator for Reason for Rejection, the Item is open can for processing again

Let us see how it is working in SAP.

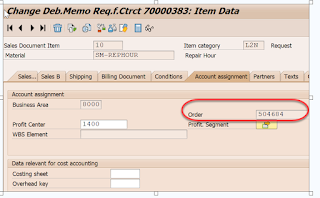

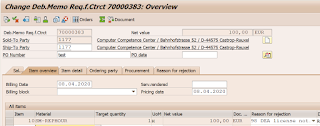

for testing, i am using a Debit Memo Request ( which is service Item) from Service Order- SAP CS module

Process:

1. Create a Service Order

2. Confirm the service Order

3. check for Actual Cost

4. Use DP90 to generate Billing Request for the service Order

i have Created one service Order, confirmed the cost and Ran DP90.

Inserting a Reason for Rejection. for Test Purpose i have chosen two ROR

1. 98 ( without OLI indicator)

2. P1 ( with OLI indicator)

Case 1:

Let us insert 98 as ROR to the Item and see the impact.

As the item is set to ROR, i will try to Create DP90 for same service Order again, just see the impact

after the ROR set as well, the DP90 does not allow to create a new Debit Memo Request

Case 2:

Let us insert P1 as ROR to the Item ( which is set to OLI)

Now see the amounts when we run DP90 for the same service Order, system will revoke all amounts and again ready for Billing Request

and Upon saving, it will generate a new Billing Request.

Please test and provide your feedback and suggestions

thank you

Too Good

ReplyDeleteGood explaination

ReplyDelete