In the other Blog, we have seen how to Activate " HOW TO ACTIVATE MATERIAL LENGTH"

https://santoshvemuri.blogspot.com/2020/04/s4hana-sourcing-and-procurement.html

now we will see, what kind of errors we could get and how to handle them

As we know there are two transactions to be set for material length Extension

1. FLETS

2. OMSL

, let us assume, we have activated Material Length ( refer below screen), which means system can now allow us to create material beyond 18 Characters

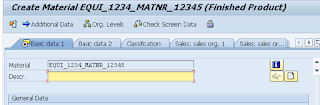

Now we will try to create a material master in MM01 with more than 18 and see!!

We get error as the length of the material is Longer than it is set, how does this error trigger and what we have to do??

This error triggered from OMSL setting, where the material length is defined as 18

So let us try to change this length and see how it works

i have set material No length as 30 Characters and tried to Create a material beyond 18 characters

After i set OMSL, system now allows to take beyond 18

so always make changes in OMSL if your requirement is to extend the material beyond 18

FLETS is to activate the length extension

When we try to enter the Material with Only Numeric such as 123456................ ( all numbers greater than 18)

then check the behaviour of system ⏬⏬⏬

The error we still get is due to only Numericals, Always for Numericals system should consider only 18 and and leading zero will be added as per OMSL

you can see how system controls is programmatically

From the above screen, system check the input material has length of 27, but the field tmcnv-maske in the standard conversion program # LOMCVU01 is hard coded for only 18

just try to check these two settings in S/4HANA. This is available from initial Version of S/4HANA 1511 till 1909

Good Luck

Keep it up, Nice Blog

ReplyDelete